Battery Tester

Battery Conductance Tester MICRO-200 adopts currently the world's most advanced conductance testing technology to easily,quickly and accurately measure the actual cold cranking amps capability of the vehicle starting battery, healthy state of the battery itself, and common fault of the vehicle starting system and charging system, which can help maintenance personnel to find the problem quickly and accurately, thus to achieve quick vehicle repair.

Car Battery Tester/Analyzer MICRO-200 for 12 Volt Vehicles is a one of our Battery Tester Tools, you can buy Car Battery Tester/Analyzer MICRO-200 for 12 Volt Vehicles from 3cseller.com.

Wholesale Top quality X-PROG Box ECU Programmer, Kess ECU Programmer, SBB Pro2 Key Programmer, Volvo 88890300 Vocom Interface, Cummins INLINE 7 Data Link Adapter

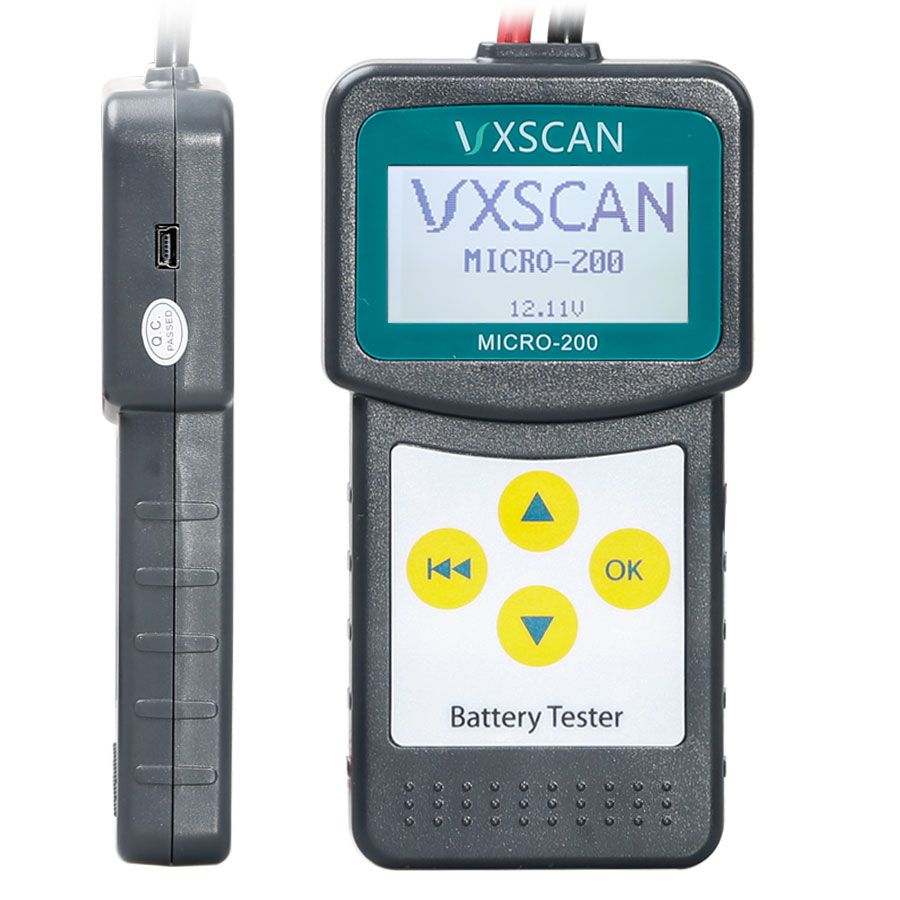

images of Car Battery Tester/Analyzer MICRO-200 for 12 Volt Vehicles

MICRO-200 Car Battery Conductance Tester

There are three language versions:

AD112: Mainland Version Japanese, Korean, Russian, English

AD112-B: Nordic Language version: English, Dutch, Swiss, Finnish, Norwegian, Danish

AD112-C: Western European language version: English, French, German, Spanish, Italian, Polish

Product specification:

1、One year warranty and lifetime maintenance

2、Application: 12V automotive cranking lead acid battery and 12v car system test

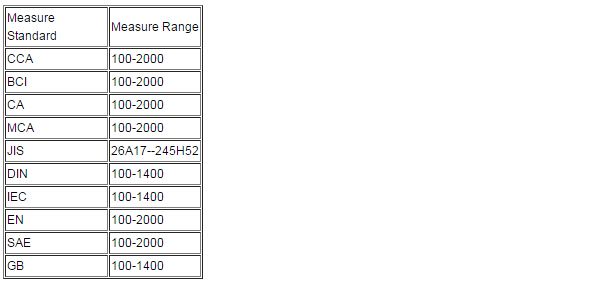

3、Measure Range:

4、Working Environment Temp: -20℃-50℃

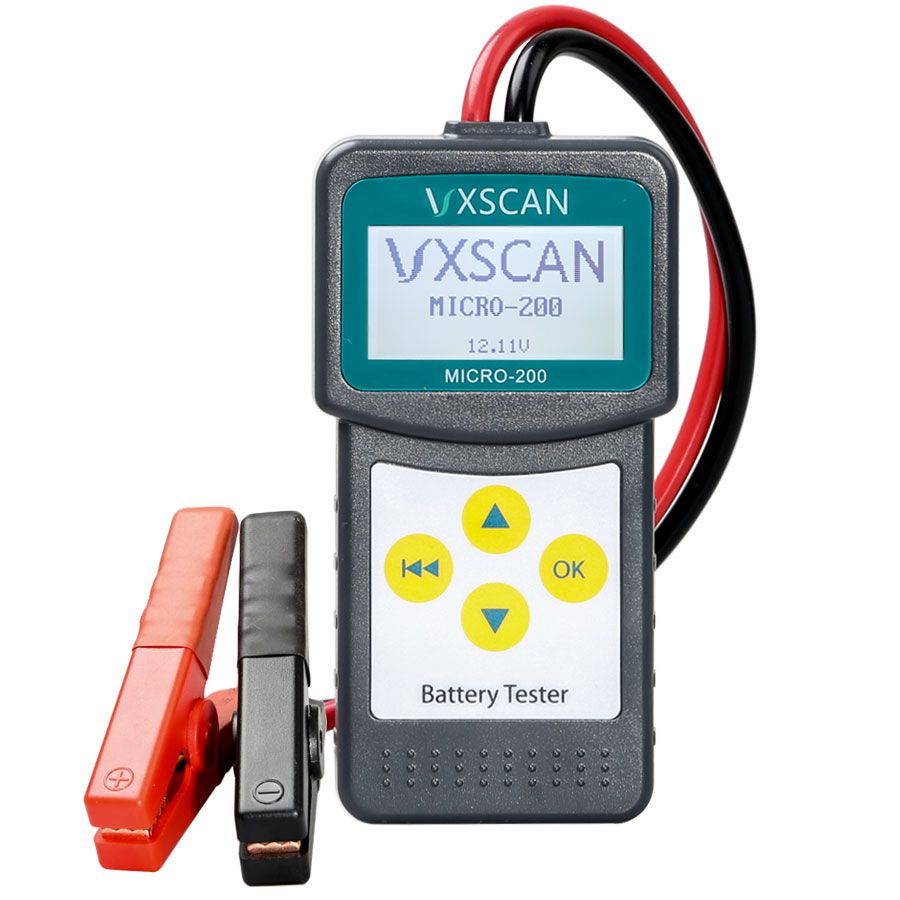

5、Special test clip: Double conductor Kelvin clamp

6、Housing Material: Acid-resistant ABS plastic

7、Measure Range: 30AH-200AH

8、Voltage Measure Range: 7-30VDC

How to use:

1.Connect the red test clamp with battery anode and the black one with cathode, the tester will power on automatically.

Voltage battery below 7.0VDC can’t be tested properly, then press OK key to continue.

2.According to the tester, you can press UP/DOWN key to choose:

battery test

starting system test

charging system test

battery test result

print test result

elect language

Perform Battery Test:

Select the battery test and press OK key to continue:

Input testing standard: the standard which you can see the front of the battery, such as CCA, BCI, DIN. If you can’t find any info about the standard,

you can choose GB standard. Choose GB standards would lead little tolerance.

Input rated capacity: you can see the starting current standards in front of the battery .Such as BCI/300A.

Then press OK key to start testing.

Note:

For power loss battery (such as a vehicle for a long time on hold, the battery is not charged in time; forget to close the lights, the doors resulting in serious loss of battery electric vehicle and can not be started, etc.), in the actual testing process may also be prompted to "Please replace the battery."

for such batteries, please consult the battery manufacturers, and then tested.

Starting system test:

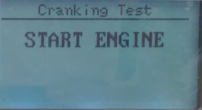

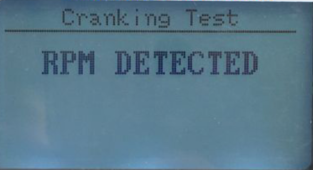

After entering the second start system test functionthe press OK key as follows:

Starting the engine as prompted, the tester will automatically complete the cranking test and display the result.

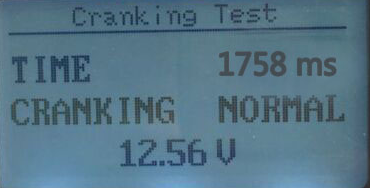

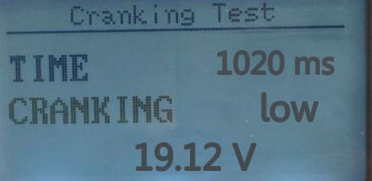

Normally, cranking voltage value lower than 9.6V is regarded as abnormal and it is OK if it is higher than 9.6V.

Test result of the tester includes actual cranking voltage and actual cranking time.

When the cranking test is abnormal, battery test result will also be displayed at the same time.

This is for the convenience of the maintenance personnel to quickly know the whole state of the starting system according to the data.

Charge system test:

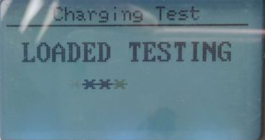

When enter the charging test, the tester will prompt "Loaded testing"

Note: Do not shut down the engine during the test. All electrical appliance and device are in OFF state. Turn on/off any electrical

appliance in the vehicle during the test will affect the accuracy of the test result.

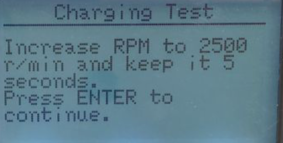

Operate accordingly to increase the engine rotating speed to 2500turns, and keep for 5 seconds.

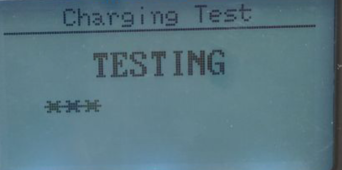

Tester starts the charging volt test after increase rev detected.

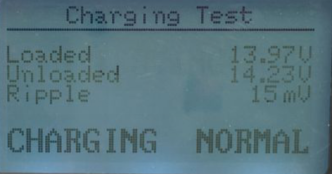

After the test finished, tester displays the effective charging volts, ripple test result and charging test result.

NOTE: If no increase rev detected, it shall be the fault of generator regulator or connection with battery failed. Tester will try 3 times to further detect, if still failed, it will skip the increase rev detect and the test result displays "No Volt Output".

Check the connection between generator and battery, then retest.

Charge Test Result:

1. Charging Volt: Normal. The generator output normal, no problem detected.

2. Charging Volt: Low. Check drive belt of the generator whether slip or running off. Check the connection between generator and battery is

normal or not. If both of the drive belt and the connection are in good condition, follow the manufacturer's suggestion to eliminate generator fault.

3. Charging Volt: High. Since most of the vehicle generators are using internal regulator, the generator assembly has to be replaced.(Some old style

cars are using external regulator, then directly replace the regulator.) The normal high volt of the voltage regulator is maximum 14.7±0.5V.

If charging volt is too high, it will overcharge the battery. Therefore, the battery life will be shortened and troubles will be caused.

4. No Volt Output. No generator volt output is detected. Check the generator connection cable, the drive belt of generator and engine whether

normal or not.

5. Diode Test: Through the test of charging current ripple, tester will find out whether the diode is normal or not. When ripple volt is too high,

it proves at least one diode is damaged. Check and replace the diode.

View test result:

After entering the forth function, then press OK key you can view the final test result.

Print test result:

About Printing function, please contact with customer service to get the download link.

Select a language:

After entering the language function, can press up/down key to choose it.

Package List:

1pc x MICRO-200

Go to Buy: Car Battery Tester/Analyzer MICRO-200 for 12 Volt Vehicles